Hydraulic valves are integral parts of hydraulic power systems. These types of valves enable the precise customization and control of fluid flow and pressure within hydraulic systems, thus enabling the safe transmission of hydraulic fluid for energy purposes. Generally speaking, a valve refers to any mechanical part (with sealing properties) that somehow regulates the flow of a fluid. Valves also work with non-liquid fluids such as gases. Read More…

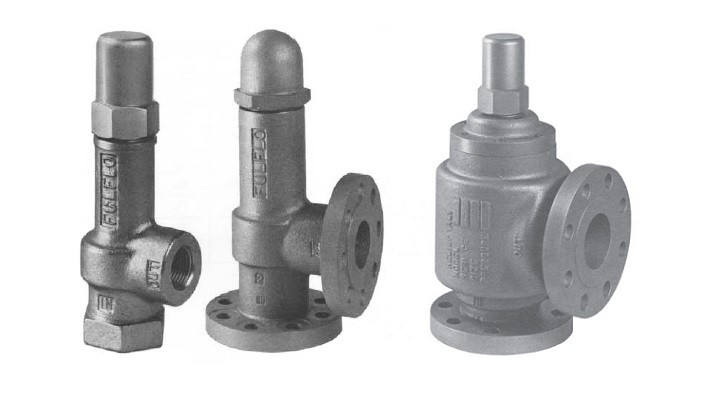

Since 1912, Fulflo Specialties has been providing "chatter free" products that modulate to regulate pressure. The company is able to provide customers with an extensive line of parts, which can mount in any position.

Bermad has been a world wide leader in the manufacturing of high quality hydraulic control valves for 45 years. Bermad’s products are prevalent in the irrigation, water works, and fire protection industries. Bermad is committed to the environment as it maximizes water use efficiency and is constantly upgrading manufacturing methods. Bermad has subsidiaries in Australia, Brazil, China, and Italy.

Doering manufactures valve and pump products for fluid power applications. Our valves include hydraulic flow control valves, gas valves, stainless steel hydraulic valves, hydraulic pressure control valves, hydraulic poppet valves and hydraulic spool valves. Download our product catalog from our site.

Since 1983, HUSCO International has been a global leader in providing the major international markets with manufactured components. Among our products are a variety of hydraulic control valves and flow rates. Target applications include construction, material handling, agricultural tractors and other general applications as well. ISO 9001:2008 certified.

More Hydraulic Valve Manufacturers

Valves are used to continue and discontinue flows, modify flow rates, reroute the direction of a flow, and regulate or relieve pressure (among similar purposes). Due to the wide variety of valve types, several different methods of classifying valves exist. It should be noted that the term hydraulic valve specifically refers to the application of a specific type of valve. In other words, a hydraulic valve is simply any type of valve that acts on hydraulic fluid.

History

Hydraulic systems have existed in some way or another since the sixth century BC, when the Mesopotamians and Egyptians used water power for irrigation. Use of hydraulics was also seen in the Hellenistic age and in ancient Persia, China, Sri Lanka, and Rome. The modern age of hydraulics began in the early 1600s, with the innovations of scientists like Benedetto Castelli and Blaise Pascal. Pascal, in particular, played a pioneering role in the field of modern hydraulics.

Pascal’s law summarizes the basis upon which the principles of hydraulics are founded. In essence, this law states that when pressure is placed on any point of a confined liquid, such pressure will transmit equally to all other parts of the confined liquid. Correspondingly, if pressure increases at any point in a confined liquid, equal and proportional increases will appear at all other points in the confined liquid. It is important to note that Pascal’s Law is made possible by the fact that liquid is incompressible. It is equally important to note that it does not apply to liquids which are not confined in some type of enclosed area. Using this principle, engineers and scientists have successfully designed systems that generate, control, and transfer power via pressurized fluids, eliminating much need for manual human effort. (Fuller explanations of Pascal’s Law can be found at treatments of other hydraulic parts, including our sites on hydraulic pumps and hydraulic cylinders).

Parts

Most hydraulic valves minimally consist of a main casing, a bonnet, a seat, and a disc. The main casing is the valve’s outer enclosure; it contains all the internal components, which are collectively called the trim. Most often, the casing is made from a metallic or plastic material. Common metallic materials include steel, stainless steel, alloyed steel, cast iron, bronze, brass, and gunmetal (red brass), while among the most common plastic options are PVC, PVDF, PP, and glass-reinforced nylon.

The bonnet is a semi-permanent, removable part of the valve that acts as a cover. For access to interior parts of the valve, the bonnet needs to be removed. Some valves do not have a bonnet because of the way they are constructed. (One example of such a valve is a plug valve.)

The term seat refers to the interior surface of the casing, which connects to the disc in order to create a leak-proof seal. The seat typically possesses sealing made of either rubber or plastic.

Finally, the disc (also called a valve member) is the part of the valve that slides into the seat to restrict flow and prevent leaking.

How They Work

Hydraulic valves can only be properly understood within the context of entire hydraulic systems. An entire unit that generates power hydraulically is known as a hydraulic power pack or a hydraulic power unit. Such packs or units typically consist of a reservoir, a pump, hydraulic valves, and hydraulic actuators such as motors or cylinders.

The purpose of hydraulic valves within a hydraulic power pack is to connect the power source (i.e., the pump) to the actuators which translate hydraulic power into mechanical motion (i.e. hydraulic cylinders, hydraulic motors). Through its valves, a hydraulic power system can supply its actuators with hydraulic fluid and modify the flow of such fluid as needed.

While functional, valves generally have at least two settings: open and closed. Generally speaking, fluid may flow freely through the valve if it is open. Conversely, fluid flow is restricted if the valve is closed. Valves with a default status of open are also known as open center valves, while valves with a default status of closed are known as closed center valves.

Valves are either open or closed based on the positioning of their interior pieces; more specifically, a valve’s status depends on whether or not the disc is inside the seat. Hydraulic valves (and especially ones used for directional control) are often referred to as spool valves since they visually resemble spools of thread (by containing interior trim within exterior housing). The flow of hydraulic fluid (or lack thereof) is dependent on the position of the interior “spool” portion of the valve within the exterior housing. The default or “neutral” position of many valves has the spool in a central position which blocks the flow of hydraulic fluid. In order to open the valve and let fluid through, the spool simply slides to one side of the housing and away from the neutral position. Nowadays, many hydraulic valves also allow for partial flow obstruction.

Types

As alluded to in the introduction, hydraulic valves can be categorized in several different ways. Some methods of categorization emphasize a valve’s physical characteristics or construction. Other methods emphasize a valve’s method of actuation or control. Still other categorization methods classify hydraulic valves according to their specific application or function.

Classifications by Construction

A common way to label hydraulic valves is by its number of ports. The term port simply refers to an avenue that hydraulic fluid can use to flow into or out of a valve. Standard hydraulic valves are double ports, since they possess both an inlet port (to draw in fluid from the pump) and an outlet port (to pass fluid on to the actuators). However, hydraulic valves can also be three-port, four-port, or multi-port. Hydraulic manifolds are another type of valve which is classified primarily on the basis of physical characteristics. Such mechanisms are actually separate hydraulic valves that are connected to one another within hydraulic systems.

Hydraulic cartridge valves (also known as slip in valves, logic valves, or 2/2-way valves) are some of the more popular valves which derive their classification from their configuration. These valves are screwed into a threaded cavity and are typically composed of only a sleeve, a cone or poppet, and a spring. They open when incoming fluid pushes the holding cone or poppet (held in place by the spring) aside. The ease of installing cartridge valves makes them very popular in the hydraulic world.

Overall, hydraulic valves vary widely in physical shape and size. They can range in size from less than an inch to a foot long. On average, they can fit in the palm of a hand. The broad physical variety that characterizes hydraulic valves directly affects their differing uses.

Classifications by Actuation/Control

It is important to note that valves can only function properly with some type of valve actuator. While not strictly a part of the valve itself, valve actuators are important since they are responsible for actually moving the machinery within a valve to change its status. Valve actuators can be either manual or automatic.

An example of a manually operated valve is the hydraulic ball valve. This valve derives its name from a spherical, internal disk containing a hole and is activated with a handle that can be quickly rotated 90° between opened and closed positions. When the valve is open, the hole in the ball disk lines up with the direction of fluid flow and allows fluid to pass through. When the valve is closed, the hole is not lined up with the fluid flow, thus blocking the flow of fluid.

Valve balls are perforated and most often made of nickel, brass, stainless steel, or titanium. (Sometimes, they are made of plastic, like PVC, PP, ABS, or PVDF.)

Many manually operated hydraulic valves typically require high amounts of force in order to successfully stop high-pressure flows of hydraulic fluid. Thus, many manual hydraulic valves other than ball valves are operated by oversized wheels, levers, and even hydraulic rams.

Other hydraulic valves are electrically operated, and/or guided remotely with computer controls. Hydraulic solenoid valves are an excellent example of such valves. They open and close based on the charge of a magnetic field that pushes on a plunger. The magnetic field is signaled by a current, which is received by a wire coil when the solenoid converts electrical energy into mechanical energy. Other types of electronically or remotely controlled hydraulic valves can be found in places such as construction sites, where they are critical to the operation of many hydraulically-powered construction machines.

Classifications by Application or Function

Overall, mechanical valves in general are often classified by the exact function they are designed to exact on a fluid (e.g. completely cutting off a flow, preventing backflow, etc.). Since hydraulic valves are essentially general types of valves expressly applied in hydraulic scenarios, hydraulic valves are often also classified according to their exact regulatory function.

Control valves are valves specifically designed to control or modify the amount and speed of a fluid flow. These types of valves are particularly capable of occupying a spectrum of positions between fully open and fully closed. They are sometimes further classified as pressure control valves and flow control valves. (Control valves contrast with simple on/off valves or shutoff valves, which are designed to completely stop or start a fluid flow rather than simply modifying it.)

Directional control valves (or simply directional valves) may arguably be the “basic” type of mechanical valve, since their purpose is to control or modify the direction (rather than the amount) of fluid flow. On average, many standard hydraulic “spool” valves are used expressly for directional control and occupy a few discrete positions. Check valves (or non-return valves) are specific types of directional control valves that are used to force fluid flow in one direction only; if fluid within a hydraulic system somehow begins flowing in an undesirable direction, the check valve will close and block the flow. Check valves are critical to hydraulic systems in environments where substances of varying compositions and pressures must be kept separated (such as wastewater management plants).

Proportional valves can be considered as “extensions” of directional control valves. In addition to modifying flow direction, these types of valves can occupy intermediate positions and carry an output flow that is unequal to the input flow. In other words, proportional valves are designed to control the speed as well as the direction of fluid flow. (From this perspective, they can also be considered as extensions of control valves, which are designed to control the speed and amount of fluid flow.)

Pressure relief valves (or simply relief valves) are primarily designed to keep hydraulic systems from over-pressurizing. Instead of closing when undesirable conditions are met (such as check valves), these types of valves open in order to draw hydraulic fluid back into the reservoir when internal pressure has exceeded a certain point (e.g. due to a blocked pipe in the system).

It should be noted that differing functions accomplished by the aforementioned valves can also be performed by other, more specific types of valves. For example, hydraulic cartridge valves are often used for directional or check control as well as pressure or flow control. Beyond these few examples, there are many other unique valve types with individual functions. Hydraulic needle valves, for instance, are composed of small ports and threaded plungers. Their unique shape allows them to regulate flow in extremely tight spaces.

Accessories

Other components associated with hydraulic valves include springs, gaskets, and stems. Those valves that include springs do so in order to shift the disc and control repositioning. Common spring materials include stainless steel, zinc-plated steel and, for work with exceptionally high temperatures, Inconel X750. Gaskets are mechanical seals, usually made from an elastomer. Their purpose is to prevent leakage of fluids from the valve or in between separate areas of the valve. The term metal face seal refers to a gasket that is located between two fittings in a sandwich-like arrangement. Stems are not always present, because they are often combined with the disc or handle. However, when present, they transmit motion from the controlling device, like the handle, through the bonnet and to the disc.

Hydraulic valves can be connected to hydraulic systems with a variety of different mechanisms. Some of these mechanisms include flanges (bolt or clamp), welds (butt or socket), union connections, and fittings (tube or compressions).

Applications

The value of hydraulic valves to the industrial world is inextricably bound up in the value of hydraulic systems as a whole. Overall, hydraulic power systems offer energy sources that are simpler and safer than other types (such as electrical power systems) while still being incredibly effective. Hydraulic valves are thus valued and widespread because they enable effective movement of hydraulic fluid, which forms the “lifeblood” of hydraulic power systems.

Hydraulic valves make flow control possible for many, many applications, including those in the aerospace, automotive, chemical and laboratory, construction, cryogenic, fire and heating services, food processing, fuel and oil, gas and air, irrigation, medical, military, process control, refrigeration, and wastewater industries.

Considerations

Selecting the appropriate hydraulic valves for a given application is a critical task that requires careful consideration of several key factors. One of the primary considerations is the proper flow coefficient (Cv) for the application. The flow coefficient represents the valve’s ability to control fluid flow and is essential for ensuring the right amount of fluid passes through the system. Choosing a valve with the correct Cv value ensures optimal performance and prevents issues such as pressure drops or flow restrictions.

Another crucial factor is the maximum temperature that the hydraulic system will encounter. Hydraulic systems can generate substantial heat during operation, and selecting valves capable of withstanding the maximum expected temperature is vital to avoid performance degradation or even valve failure. High-temperature applications may require valves made of specialized materials or with advanced thermal resistance properties.

The level of rigor in a hydraulic application also influences valve selection. Some applications, such as industrial or heavy-duty machinery, require robust and reliable valves capable of withstanding harsh conditions and heavy loads. In contrast, less rigorous applications may allow for more cost-effective and lighter valves without compromising safety and efficiency.

Additionally, considering the number and type of ports or directional stages needed in a hydraulic scenario is essential. Different hydraulic systems may require various configurations of valves to control fluid flow, pressure, and direction effectively. Understanding the system’s requirements and the specific tasks each valve needs to perform is crucial in ensuring the hydraulic system’s overall efficiency and functionality.

In conclusion, selecting hydraulic valves involves a comprehensive analysis of factors such as the appropriate flow coefficient, maximum temperature tolerance, the level of rigor in the application, and the required ports or directional stages. A thorough understanding of the application’s demands, along with the properties and capabilities of different valve types, is essential to make informed decisions that lead to a well-functioning and reliable hydraulic system. By considering these factors in conjunction, engineers and system designers can ensure optimal performance and longevity for their hydraulic applications.

Choosing the Proper Hydraulic Valve Supplier

To ensure you have the most positive outcome when purchasing hydraulic valves from a hydraulic valve supplier, it is important to compare several companies using our directory of hydraulic valve suppliers. There, each hydraulic valve supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each hydraulic valve business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple hydraulic valve businesses with the same form.

Hydraulic Cylinders

Hydraulic Cylinders Hydraulic Lifts

Hydraulic Lifts Hydraulic Motors

Hydraulic Motors Hydraulic Presses

Hydraulic Presses Hydraulic Pumps

Hydraulic Pumps Hydraulic Seals

Hydraulic Seals Hydraulic Valves

Hydraulic Valves Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services