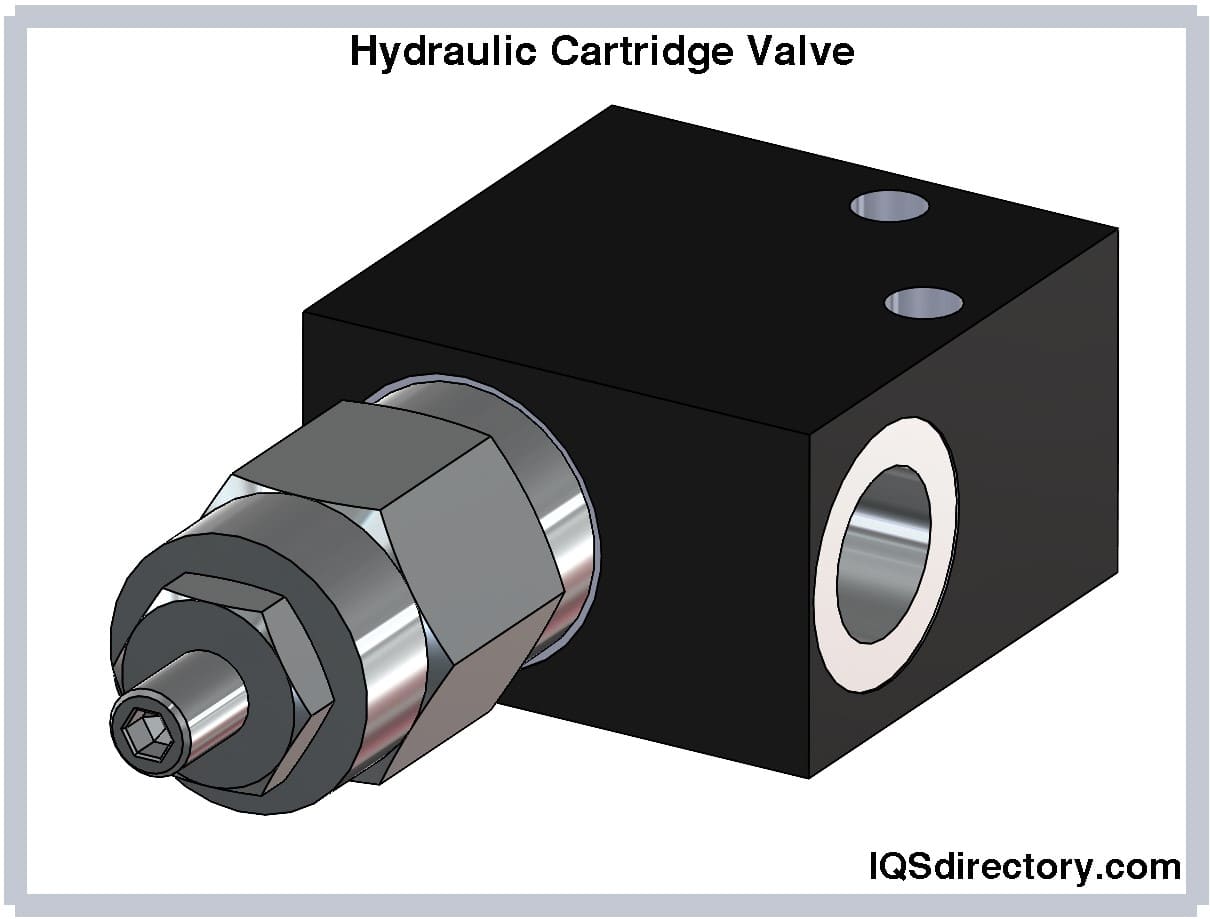

Hydraulic cartridge valves are valves that are threaded to screw into other applications. They can refer to directional, pressure, or flow control valves. Cartridge valves can be referred to as slip-in valves. They are small, affordable, and have quick switching rates. Cartridge valves are ideal if you don’t want to worry about leaks when using high-flow equipment. They are useful in multiple industries. Read More…

Since 1912, Fulflo Specialties has been providing "chatter free" products that modulate to regulate pressure. The company is able to provide customers with an extensive line of parts, which can mount in any position.

Bermad has been a world wide leader in the manufacturing of high quality hydraulic control valves for 45 years. Bermad’s products are prevalent in the irrigation, water works, and fire protection industries. Bermad is committed to the environment as it maximizes water use efficiency and is constantly upgrading manufacturing methods. Bermad has subsidiaries in Australia, Brazil, China, and Italy.

Doering manufactures valve and pump products for fluid power applications. Our valves include hydraulic flow control valves, gas valves, stainless steel hydraulic valves, hydraulic pressure control valves, hydraulic poppet valves and hydraulic spool valves. Download our product catalog from our site.

Since 1983, HUSCO International has been a global leader in providing the major international markets with manufactured components. Among our products are a variety of hydraulic control valves and flow rates. Target applications include construction, material handling, agricultural tractors and other general applications as well. ISO 9001:2008 certified.

More Hydraulic Cartridge Valve Manufacturers

How Hydraulic Cartridge Valves Function

Cartridge valves are made of a sleeve, a valve cone, and a closed spring. Pilot-operated check valves with an equal area at both ports are popular because they are easy to install in hydraulic systems. Fluid arriving from either port will push the holding poppet open. These valves are unidirectional and lack communication holes through the poppet to allow fluid to pass behind it. Normally, a thin spring holds the poppet in place during shutdown. It easily succumbs to allow fluid to simply pass through the valve.

Types of Hydraulic Cartridge Valves

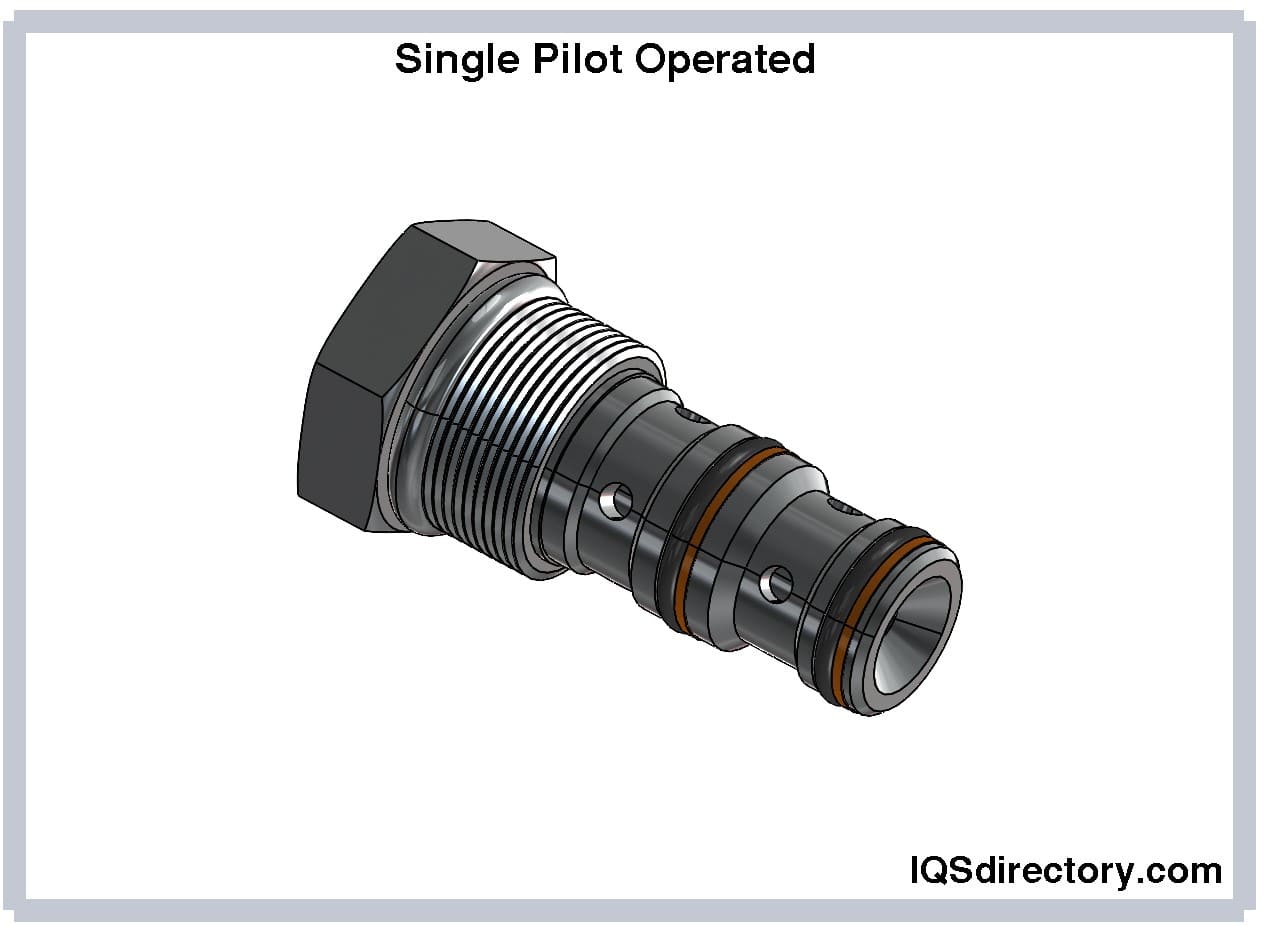

Single Pilot Operated Check Valves

Pilot-operated check valves block the flow in one direction until the right pilot pressure is applied. This indicates that the poppet inside the check valve stays sealed in the absence of the required pilot pressure. Once the necessary pressure has been applied, the fluid can freely flow in the opposite direction. This process helps lock the system's dual-acting cylinder. The pilot piston and threaded cartridge valves are the two common hydraulic pilot-operated check valves.

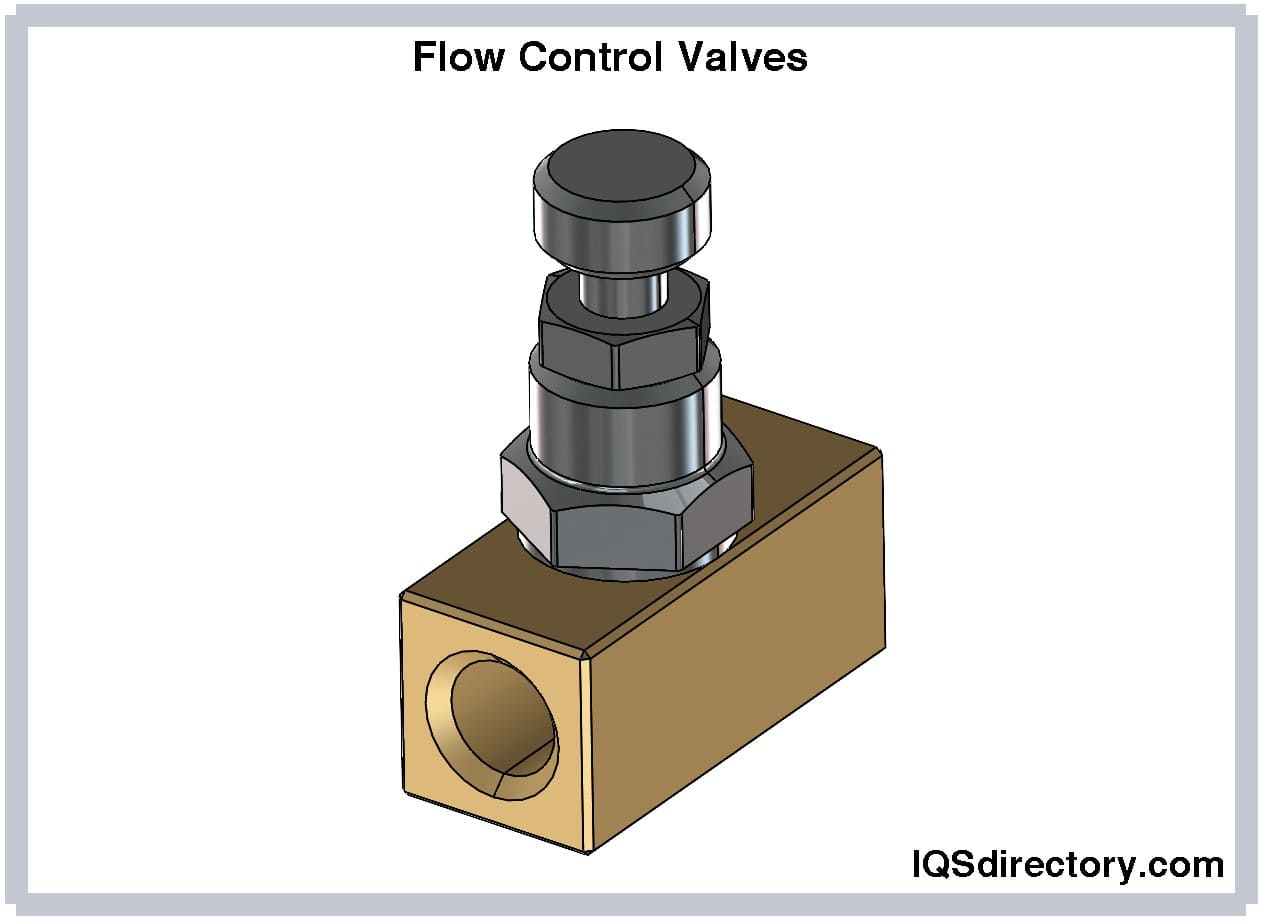

Flow Control and Flow Divider Valves

Hydraulic flow control valves help control the flow rate, which affects pressure; hydraulic flow control valves are crucial. Unregulated speed can harm a hydraulic system’s pumps and actuators or render the entire system ineffective. Flow divider valves divide the flow of the fluid. They can be used in the opposite direction to merge separate hydraulic fluid flows into a single stream. The dividing and combining functions are exact and independent of the flow’s pressure or viscosity.

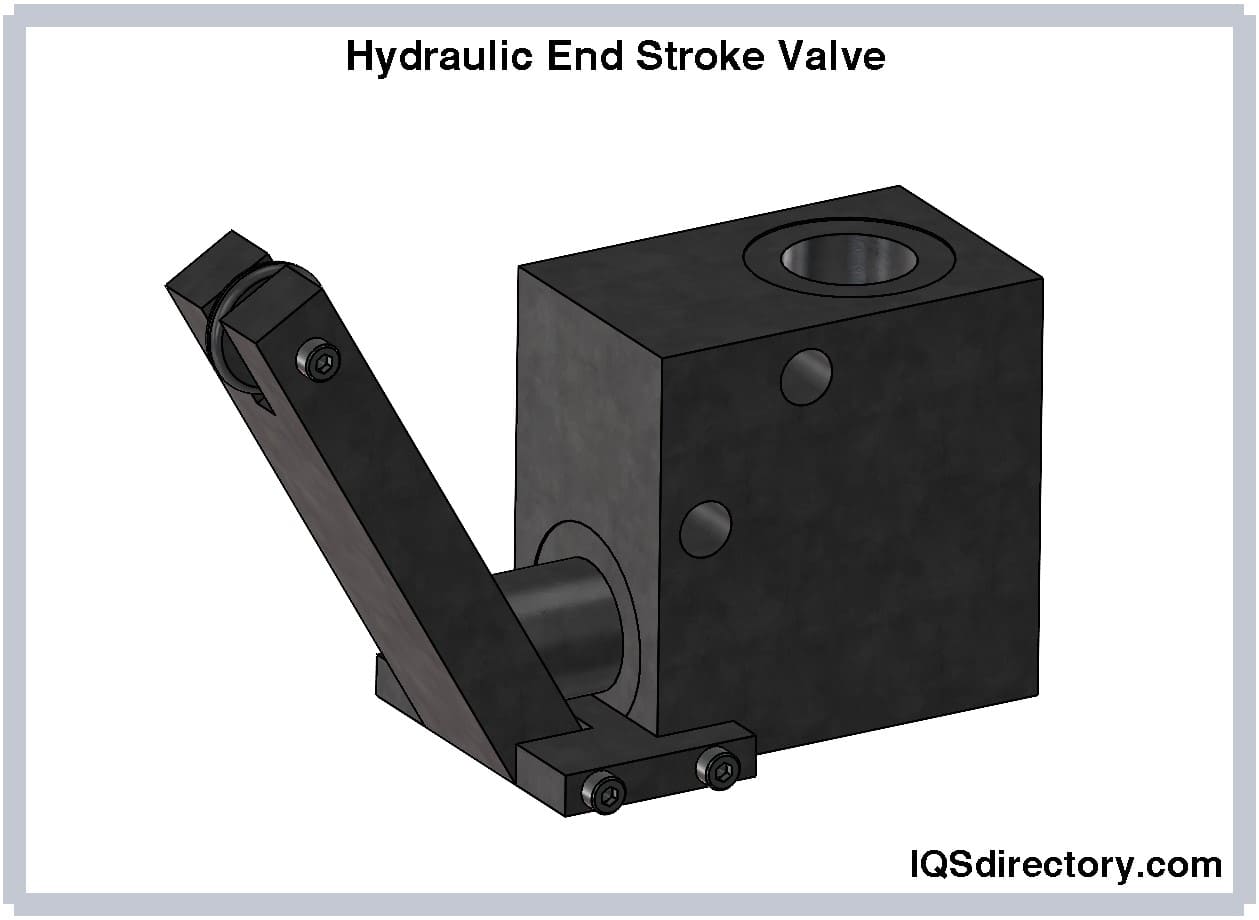

End Stroke Valves

End stroke valves are mounted on a branch to release pressure. End stroke valves use a pusher to move fluid from one exit to the other. there are open and closed models. Open models are intended to be open and closed by user interaction. These valves can be opened or closed by pushing or pulling on a slider, while some models have fluid levers for simple adjustment. Closed models operate similarly but instead are only opened by user interference. Both versions will immediately and completely stop the flow through the valve when they are closed.

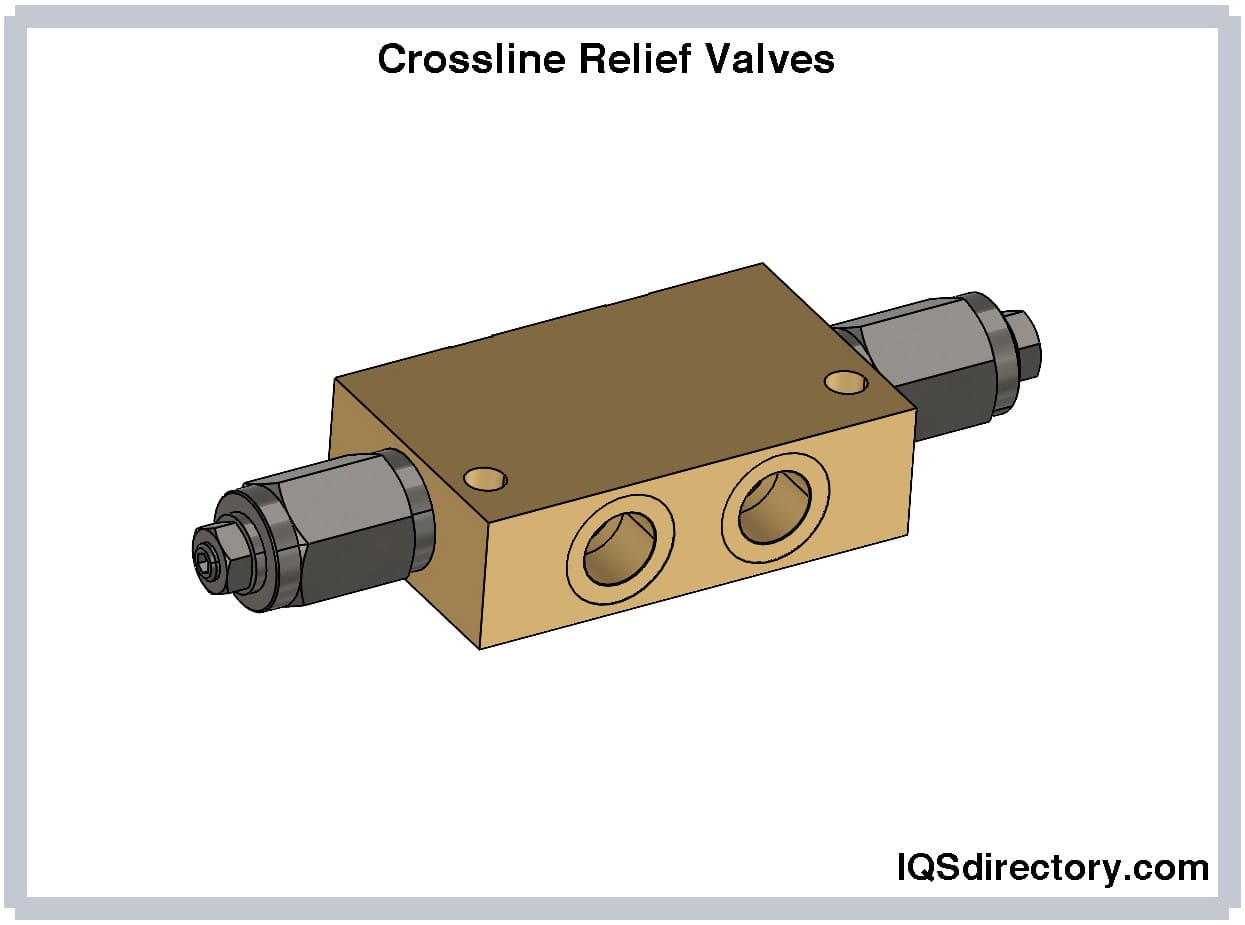

Crossline Relief Valves

Hydraulic crossline relief valves are a popular choice. If your system uses a fixed-volume pump, a relief valve is necessary to safeguard from excessive pressure. There are many kinds of relief valves, including direct-acting and pilot-operated valves.

Hydraulic Diverter and Ball Valves

Hydraulic diverters and ball valves divert flow from a single source to many lines. This is especially helpful in dumping operations. One outlet allows fluid to pass from a shared source to the vital hydraulic component. Simultaneously, the other outlet empties or recycles extra fluid. The second outlet often loops back into the system to minimize waste. Common models include two-way ball valves to 6-way solenoid diverters. Their uses are flexible.

Application of Hydraulic Cartridge Valves

- Deep sea and decompression

- Assemblies for directional controls

- Orifice limiters

- Pressure compensators

- Systems for relieving pressure testing apparatus

Choosing the Proper Hydraulic Cartridge Valve Manufacturer

To ensure you have the most beneficial outcome when purchasing hydraulic cartridge valves from a hydraulic cartridge valve manufacturer, it is important to compare several companies using our directory of hydraulic cartridge valve manufacturers. Each hydraulic cartridge valve manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each hydraulic cartridge valve business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple hydraulic cartridge valve companies with the same form.

Hydraulic Cylinders

Hydraulic Cylinders Hydraulic Lifts

Hydraulic Lifts Hydraulic Motors

Hydraulic Motors Hydraulic Presses

Hydraulic Presses Hydraulic Pumps

Hydraulic Pumps Hydraulic Seals

Hydraulic Seals Hydraulic Valves

Hydraulic Valves Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services