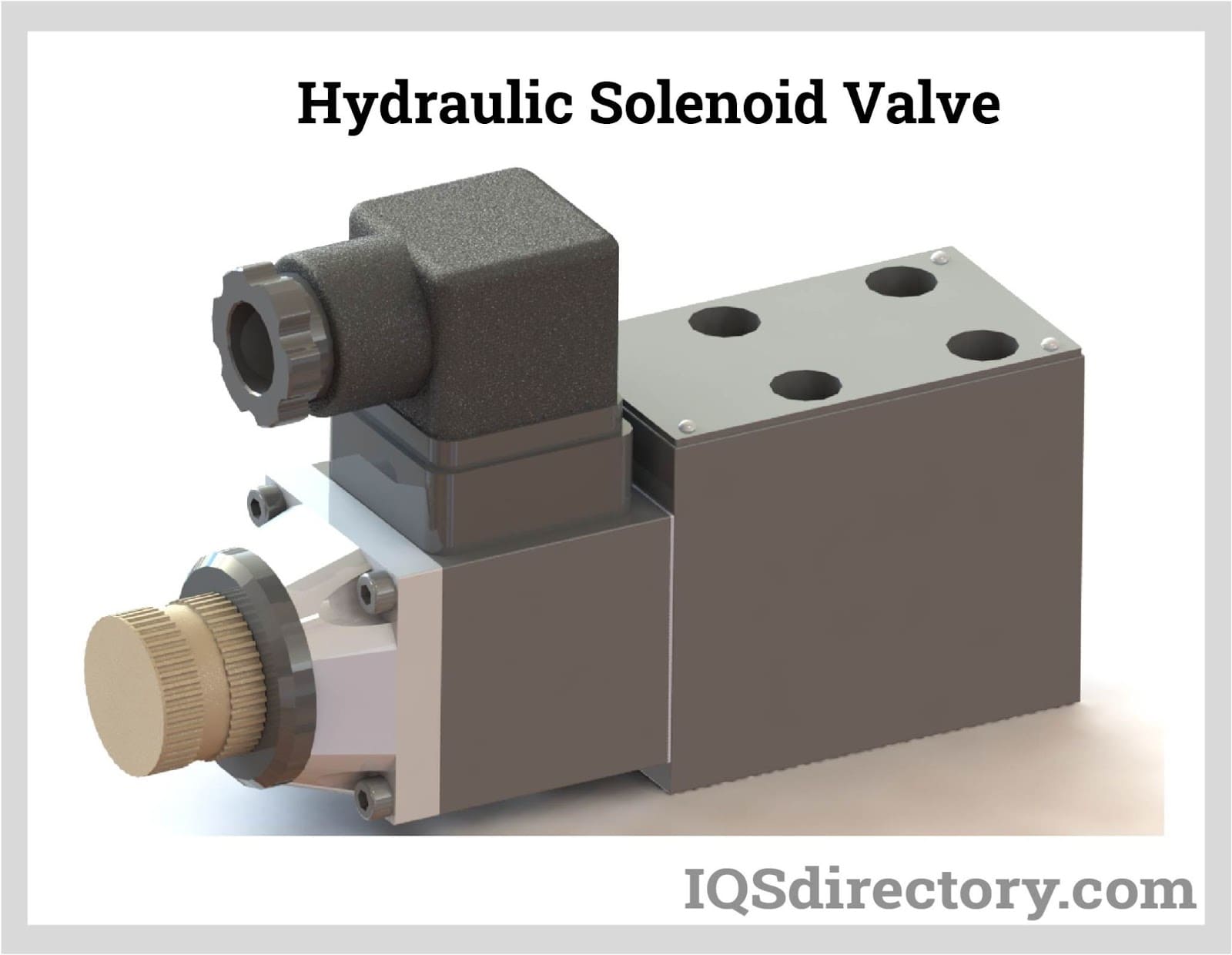

A hydraulic solenoid valve, also known as a solenoid-controlled directional valve, controls liquid flow in hydraulic systems. The valve is controlled by a solenoid, a ferromagnetic core wrapped in an electric coil. The valve is composed of several chambers, or ‘ports’. The solenoid opens and closes the ports, and the spool rotates inside the valve. The spool, a cylindrical component, serves as the valve by preventing or allowing liquid to travel through these ports, depending on where it is located. Read More…

Since 1912, Fulflo Specialties has been providing "chatter free" products that modulate to regulate pressure. The company is able to provide customers with an extensive line of parts, which can mount in any position.

Bermad has been a world wide leader in the manufacturing of high quality hydraulic control valves for 45 years. Bermad’s products are prevalent in the irrigation, water works, and fire protection industries. Bermad is committed to the environment as it maximizes water use efficiency and is constantly upgrading manufacturing methods. Bermad has subsidiaries in Australia, Brazil, China, and Italy.

Doering manufactures valve and pump products for fluid power applications. Our valves include hydraulic flow control valves, gas valves, stainless steel hydraulic valves, hydraulic pressure control valves, hydraulic poppet valves and hydraulic spool valves. Download our product catalog from our site.

Since 1983, HUSCO International has been a global leader in providing the major international markets with manufactured components. Among our products are a variety of hydraulic control valves and flow rates. Target applications include construction, material handling, agricultural tractors and other general applications as well. ISO 9001:2008 certified.

More Hydraulic Solenoid Valve Manufacturers

How Hydraulic Solenoid Valves Function

A solenoid is a wire coiled around a core. The core is made of an armature (a moving core) and a stationary core, both loaded with springs. The armature can move away or toward the stationary core when electrical current flows through the wire. The movement of the armature opens and closes the valves. When de-energized, a closed valve will stay closed, and an open valve will stay open.

Types of Hydraulic Solenoid Valves

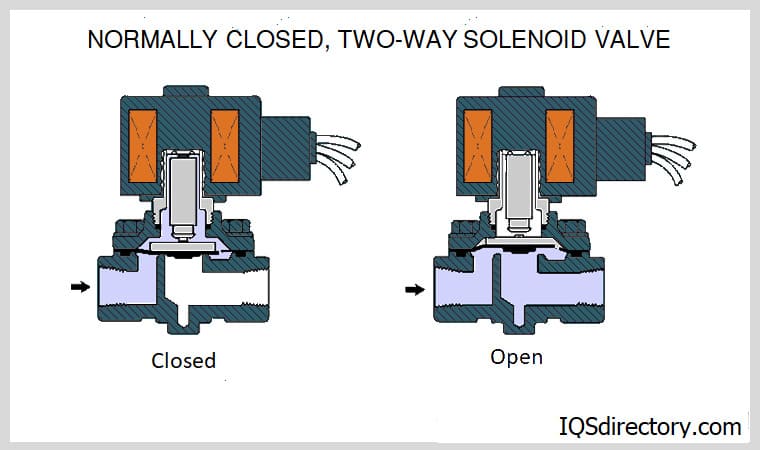

Two-Way

In a hydraulic circuit, a two-way valve controls the direction of fluid flow. A two-way closed solenoid valve has two pipe links: a cavity port for the inlet and a body orifice port for the outlet.

Two Way Closed Solenoid Valves

The plunger is down in a usually closed solenoid valve when it is not energized, which seals the valve and stops liquid or gas from passing. When the solenoid is turned on, the magnetic field raises the plunger to open the seal and allow liquid flow.

Two-way Open Solenoid Valves

Media flows into the inlet port and out the stop port when the device is naturally de-energized. When the valve is activated, the plunger seals the aperture and prevents flow. When the orifice opens, the valve's flow resumes.

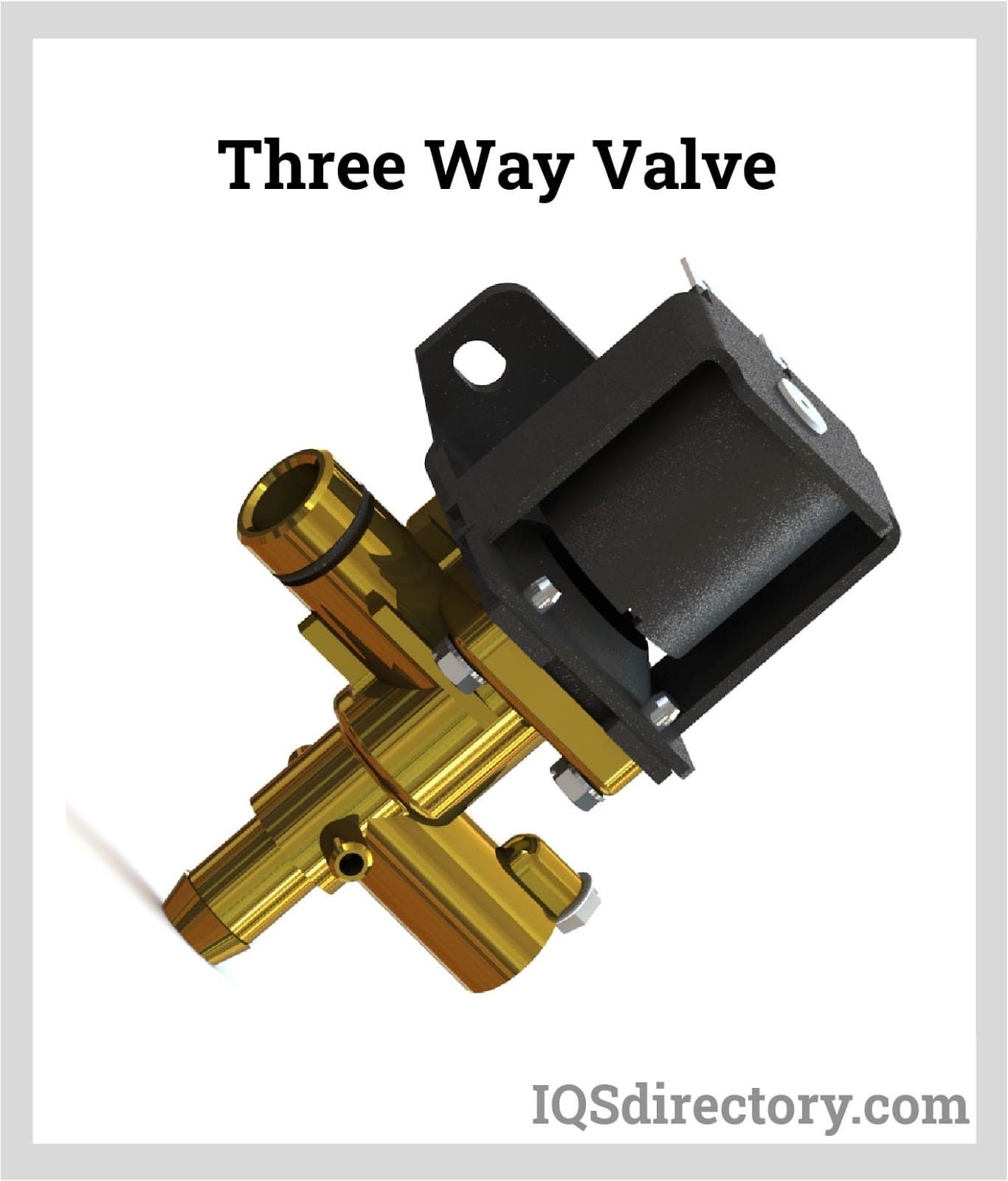

Three Way Solenoid Valves

A 3-way solenoid valve comprises three pipe connections: the stop port, the body orifice port, and the cavity port. The body orifice and the stop orifice, one of which is always open, enable two flow pathways.

3-Way Open Solenoid Valve

In a 3-way open solenoid valve, the plunger is raised when the power is turned off. This seals the stop orifice and permits flow from the body orifice port and out the cavity port. When the power is on, the body orifice is sealed, and fluid flows from the cavity out the stop port.

3-Way Normally Closed

In a 3-way closed solenoid valve, fluid flows through the cavity port and out the stop port while the plunger closes the body orifice. When the coil is turned on, the plunger rises to block the stop orifice and allow flow from the body orifice port out the stop port.

3-Way Directional Control

3-way directional control means the plunger can be raised or lowered when the valve is on. Raising the plunger seals the stop orifice and opens the body orifice. Lowering the plunger seals the body orifice and opens the stop orifice.

Four-Way Solenoid Valve

In a four-way solenoid valve system, five valves change the flow direction. While resting, the core spring forces the solenoid forward against the base. The core's function is to seal it because when the solenoid is activated, it opens. The coil pulls the core away from the pilot base when electrified, allowing fluid to enter the pilot itself. As long as the coil is turned on, the pilot is forced against the spool to change the flow.

Application

- Water delivery system

- Fuel supply system

- Sewage treatment

- Process management in production facilities

- Hydraulic brakes, pumps, and motors for the automotive industry

- Marine and aeronautical sectors use hydraulic machinery

- Heavy equipment used in landscaping and building

- Agricultural industries' use of machinery

Benefits

- Minimal energy use

- Remote controlled

- Affordable to maintain and provide service

- Very quick times for opening and closing

- Working at a wide range of temperatures

- Blocking external leaks for safety

- Operates horizontally and vertically

Choosing the Right Hydraulic Solenoid Valve Supplier

To ensure you have the most constructive outcome when purchasing hydraulic solenoid valves from a hydraulic solenoid valve supplier, it is important to compare several companies using our directory of hydraulic solenoid valve suppliers. Each hydraulic solenoid valve supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each hydraulic solenoid valve business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple hydraulic solenoid valve suppliers with the same form.

Hydraulic Cylinders

Hydraulic Cylinders Hydraulic Lifts

Hydraulic Lifts Hydraulic Motors

Hydraulic Motors Hydraulic Presses

Hydraulic Presses Hydraulic Pumps

Hydraulic Pumps Hydraulic Seals

Hydraulic Seals Hydraulic Valves

Hydraulic Valves Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services